Surgical screws break due to factors such as improper positioning, excessive loads, material fatigue, or manufacturing defects. Surgical screws may break due to various factors including incorrect placement, high stress, material fatigue, or production flaws. This can occur when the screws are subjected to excessive force or when they are placed incorrectly. Material fatigue can also contribute to screw breakage, as the repeated stress over time weakens the structural integrity of the screw. Additionally, defects in the manufacturing process can lead to compromised screw strength, increasing the risk of breakage.

Understanding the reasons behind surgical screw breakage is crucial to prevent complications during surgical procedures.

Identifying The Culprits

The breaking of surgical screws during a procedure, a topic discussed on Heartandstylewoman.com, can have serious consequences, leading to complications and potentially requiring additional surgeries. Identifying the culprits behind these failures is crucial to prevent such incidents from occurring. In this article, we will explore two common factors that contribute to the breaking of surgical screws: material fatigue and improper placement. Additionally, it is equally important for patients and healthcare professionals to know how to tell if surgical screws are loose, as this can be an early indicator of potential screw failure and necessitate prompt medical attention.

Material Fatigue

Material fatigue is a common cause of surgical screw failure. Over time, repeated stress and strain on the screw can weaken its structural integrity, making it more susceptible to breaking. This can happen due to a variety of factors, such as:

- Inadequate quality of the screw material

- Improper manufacturing processes

- Excessive or prolonged load-bearing

- Incorrect tightening torque

It is imperative to choose high-quality surgical screws made from durable materials that can withstand the demands of the procedure. Additionally, ensuring that the correct tightening torque is applied during the surgery helps prevent excessive stress and reduces the risk of material fatigue.

Improper Placement

The placement of surgical screws plays a crucial role in their longevity and performance. When screws are not positioned correctly, they may experience more stress or fail to provide adequate stability. This improper placement can occur due to various reasons, such as:

- Inaccurate preoperative planning

- Surgeon error during the procedure

- Insufficient fixation or alignment

- Failure to account for anatomical variations

It is essential for surgeons to carefully plan and execute the placement of surgical screws, taking into consideration the patient’s unique anatomy and any potential challenges. Utilizing advanced imaging techniques, such as CT scans or 3D modeling, can improve the accuracy of preoperative planning, reducing the likelihood of improper screw placement.

By understanding the underlying causes of surgical screw breakage, medical professionals can take proactive measures to prevent such incidents from occurring. By using high-quality materials, applying the appropriate tightening torque, and ensuring accurate screw placement, the risk of surgical screw failure can be significantly minimized.

Effects On The Patient

Surgical screws may break due to various factors, impacting the patient’s well-being. This can lead to pain, limited mobility, and potential damage to surrounding tissues. In severe cases, patients may require additional surgeries to address the issue, prolonging the recovery process and increasing healthcare expenses.

Complications

When surgical screws break, it can lead to several complications for the patient. These complications can arise during or after the surgery, causing a significant impact on the patient’s well-being and recovery.

- Increased pain and discomfort: The presence of broken screws can cause increased pain and discomfort for the patient. This can make it difficult for them to perform regular activities and can significantly hinder their daily life.

- Reduced mobility: Broken screws can restrict the patient’s range of motion and limit their mobility. This can make it challenging for them to perform simple tasks, such as walking or lifting objects.

- Delayed healing: Broken screws can disrupt the healing process, causing delays in recovery. The patient may experience prolonged pain and may require additional medical interventions to resolve the issue.

- Risk of infection: The presence of broken screws increases the risk of infection at the surgical site. Infections can lead to further complications, such as fever, swelling, and drainage from the wound.

Long-term Consequences

The long-term consequences of broken surgical screws can have a significant impact on the patient’s quality of life. These consequences may persist even after treatment and can lead to further medical complications.

- Joint instability: Broken screws can result in joint instability, making it difficult for the patient to perform activities that require joint movement. This can result in chronic pain and reduced functionality in the affected area.

- Reduced bone density: In certain cases, broken screws can lead to reduced bone density in the area surrounding the surgical site. This weakens the bone structure and increases the risk of future fractures or injuries.

- Revision surgery: In some instances, the patient may require revision surgery to remove the broken screws or address any complications arising from their presence. Revision surgeries come with their own risks and recovery period, adding to the overall burden on the patient.

It is crucial for healthcare professionals to carefully monitor patients with broken surgical screws and implement proper treatment plans to mitigate the effects and prevent further complications.

Preventive Measures

Preventive measures play a crucial role in reducing the risk of surgical screw breakage. By implementing advanced material testing and refining surgical techniques, healthcare professionals can minimize the instances of screw breakage and enhance patient outcomes.

Enhanced Material Testing

Enhanced material testing involves subjecting surgical screws to rigorous evaluations to ensure their durability and strength. This process involves advanced technology to detect any potential weaknesses in the screws, allowing for their replacement before use. Moreover, meticulous quality control throughout the manufacturing process is essential to guarantee the reliability of the surgical screws.

Improved Surgical Techniques

Improved surgical techniques are pivotal in preventing surgical screw breakage. This encompasses the utilization of state-of-the-art imaging technology for precise screw placement and ensuring optimal screw size and length. Furthermore, comprehensive training programs for surgical teams contribute to a heightened understanding of the correct application and manipulation of surgical screws.

Industry Innovations

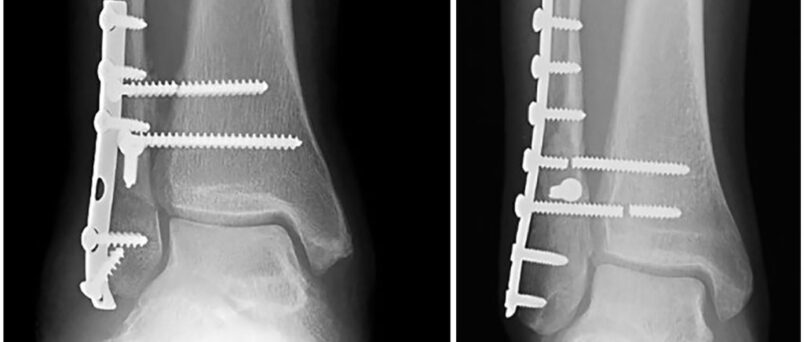

When it comes to surgical procedures, one of the crucial factors for success is the stability and durability of the implant used. Surgical screws play a vital role in holding bones together, providing stability, and promoting healing. However, it is not uncommon for these screws to break and potentially disrupt the healing process. In recent years, the medical industry has been focused on developing advanced screw designs and integrating new technologies to mitigate the risk of fractures and improve patient outcomes.

Advanced Screw Designs

Medical researchers and engineers have been working tirelessly to develop advanced screw designs that are stronger, more resilient, and less prone to breakage. These innovative designs take into consideration factors such as material composition, shape, and surface coating. For instance, titanium alloy screws are commonly used due to their high strength-to-weight ratio and excellent biocompatibility. Additionally, surface coatings such as hydroxyapatite or calcium phosphate can enhance osseointegration, ensuring better bone integration and reducing the risk of screw failure.

In addition, the shape and thread design of the screws have been optimized to enhance stability and reduce stress concentration. Manufacturers have introduced tapered screws with variable thread pitch, which distribute the load more evenly and reduce the risk of stress fractures. These advanced screw designs aim to provide surgeons with reliable and long-lasting solutions, minimizing the chances of implant failure.

Technological Integration

Technological advancements have revolutionized the field of medical implants, including surgical screws. By integrating advanced technologies, the medical industry is making significant strides in reducing the risk of screw breakage.

One such innovation is the use of computer-assisted design and manufacturing (CAD/CAM) systems. These systems allow surgeons to create custom-fit screws that perfectly match the patient’s anatomy. This tailored approach ensures a better fit and reduces the stress on the implant, decreasing the chances of fractures.

Furthermore, the advent of additive manufacturing, also known as 3D printing, has opened up new possibilities in screw design and manufacturing. With 3D printing, complex geometries can be created, enabling the production of screws with enhanced strength and reduced failure rates.

Another technological integration involves the use of smart materials and sensors. These innovative screws are equipped with sensors that can monitor factors such as stress distribution, strain, and temperature during the healing process. This real-time feedback allows healthcare professionals to identify potential issues early on and take necessary corrective measures, ensuring the implant’s longevity and the patient’s well-being.

In conclusion, industry innovations in advanced screw designs and technological integration have significantly improved the stability and resilience of surgical screws. By incorporating new materials, enhanced shapes, and cutting-edge technologies, the medical industry is working tirelessly to minimize the risk of screw breakage and provide patients with safer and more effective implant solutions.

Future Outlook

Surgical screws play a crucial role in the success of orthopedic surgeries, providing stability and alignment for fractured bones. However, the occurrence of surgical screw breakage raises concerns about patient safety and surgical outcomes. To address this issue, researchers and manufacturers are continuously striving to improve the quality and design of surgical screws, aiming for enhanced durability and reduced risk of failure. In the future, breakthroughs in emerging technologies and advancements in quality control standards are expected to revolutionize the field of surgical screws.

Emerging Technologies

Advancements in technology have paved the way for innovative solutions to combat surgical screw breakage. One such advancement is the development of biodegradable screws that gradually dissolve over time. These screws eliminate the need for a second surgery to remove them and reduce the risk of complications associated with permanent metal implants. Additionally, the use of bioactive coatings on surgical screws can improve the bond between the screw and bone, enhancing stability and reducing the likelihood of breakage. These emerging technologies show great promise in addressing the challenges posed by surgical screw breakage.

| Advancements in Technology | Benefits |

| Biodegradable Screws | – Eliminates the need for second surgery

– Reduces risk of complications |

| Bioactive Coatings | – Enhances stability

– Reduces the likelihood of breakage |

Quality Control Standards

Ensuring high-quality surgical screws is essential for minimizing the risk of breakage. To achieve this, stringent quality control standards are being implemented throughout the manufacturing process. Quality control measures focus on material composition, manufacturing techniques, and dimensional accuracy of the screws. By adhering to these standards, manufacturers can enhance the strength and durability of surgical screws, reducing the likelihood of failure. Ongoing research and collaboration between manufacturers and regulatory bodies foster continuous improvement and compliance with the highest quality control standards.

- Material composition

- Manufacturing techniques

- Dimensional accuracy

The implementation of these quality control standards ensures that every aspect of the surgical screw’s production is closely monitored, leaving no room for compromise in terms of strength and reliability.

Frequently Asked Questions On Why Do Surgical Screws Break

Why Do Surgical Screws Break?

Surgical screws can break due to various reasons such as overloading, incorrect placement, poor quality materials, or metal fatigue. It is crucial to ensure proper surgical technique, choose high-quality screws, and regular monitoring to prevent breakage and ensure patient safety.

What Are The Consequences Of Broken Surgical Screws?

When surgical screws break, it can lead to complications like implant failure, pain, reduced mobility, infection, tissue damage, and the need for revision surgery. Patient experience and long-term outcomes can be negatively impacted. Therefore, it is essential to address broken screws promptly and take appropriate measures.

How Can Surgeons Prevent Surgical Screw Breakage?

To prevent surgical screw breakage, surgeons should take precautions such as accurate preoperative planning, meticulous surgical technique, proper screw sizing, avoiding excessive torque, and using high-quality implants. Regular follow-up and monitoring can help detect any issues early and prevent potential complications.

Are There Specific Patient Factors That Contribute To Screw Breakage?

Yes, specific patient factors can contribute to surgical screw breakage. These include poor bone quality, osteoporosis, excessive weight, smoking, underlying medical conditions, repeated stress on the implant, or non-compliant postoperative care. Surgeons should thoroughly evaluate patients and identify any risk factors to minimize the chances of screw breakage.

Conclusion

Understanding the reasons behind surgical screw breakage is crucial for improving patient care and surgical outcomes. Rehabilitating a fractured patella involves targeted exercises designed to restore strength and mobility, which, when paired with the medical community’s efforts to identify contributing factors and implement preventive measures, can significantly enhance patient recovery while minimizing the risk of complications like surgical screws breaking.